Chemical mechanical polishing (CMP) technology plays a crucial role in high-precision fields such as semiconductor manufacturing and optical component processing. As the core materials in the CMP process, the performance of polishing pads and polishing solutions directly affects the polishing effect and product quality, and the testing of specific surface area and true density is of great importance for the optimization and application of these materials.

Specific surface area is an important indicator for measuring the surface characteristics of polishing materials. For polishing pads, a suitable specific surface area can provide good friction performance and adsorption capacity, ensuring appropriate cutting force and uniform material removal rate on the workpiece surface during the polishing process. A larger specific surface area is beneficial for the uniform distribution and effective adsorption of polishing solution in the polishing pad, improving the utilization rate and polishing efficiency of the polishing solution. Meanwhile, the control of the specific surface area of abrasive particles in polishing solution directly affects their dispersion and stability, which in turn affects the cutting ability and surface quality during the polishing process.

True density testing provides an important basis for evaluating the quality and performance of polishing materials. The true density of a polishing pad reflects the density of its internal structure and the uniformity of the material. High true density polishing pads usually have better mechanical strength and wear resistance, and can maintain stable performance during long-term polishing processes. Accurate measurement of true density of abrasive particles in polishing solution helps to determine the size and shape distribution of particles, optimize the formula and preparation process of polishing solution, and improve the polishing effect and surface smoothness.

Testing the specific surface area and true density of CMP chemical mechanical polishing materials is a key step in gaining a deeper understanding of material properties, optimizing polishing processes, improving product quality and production efficiency. It has important practical significance for promoting technological progress and industrial upgrading in the field of high-precision machining.

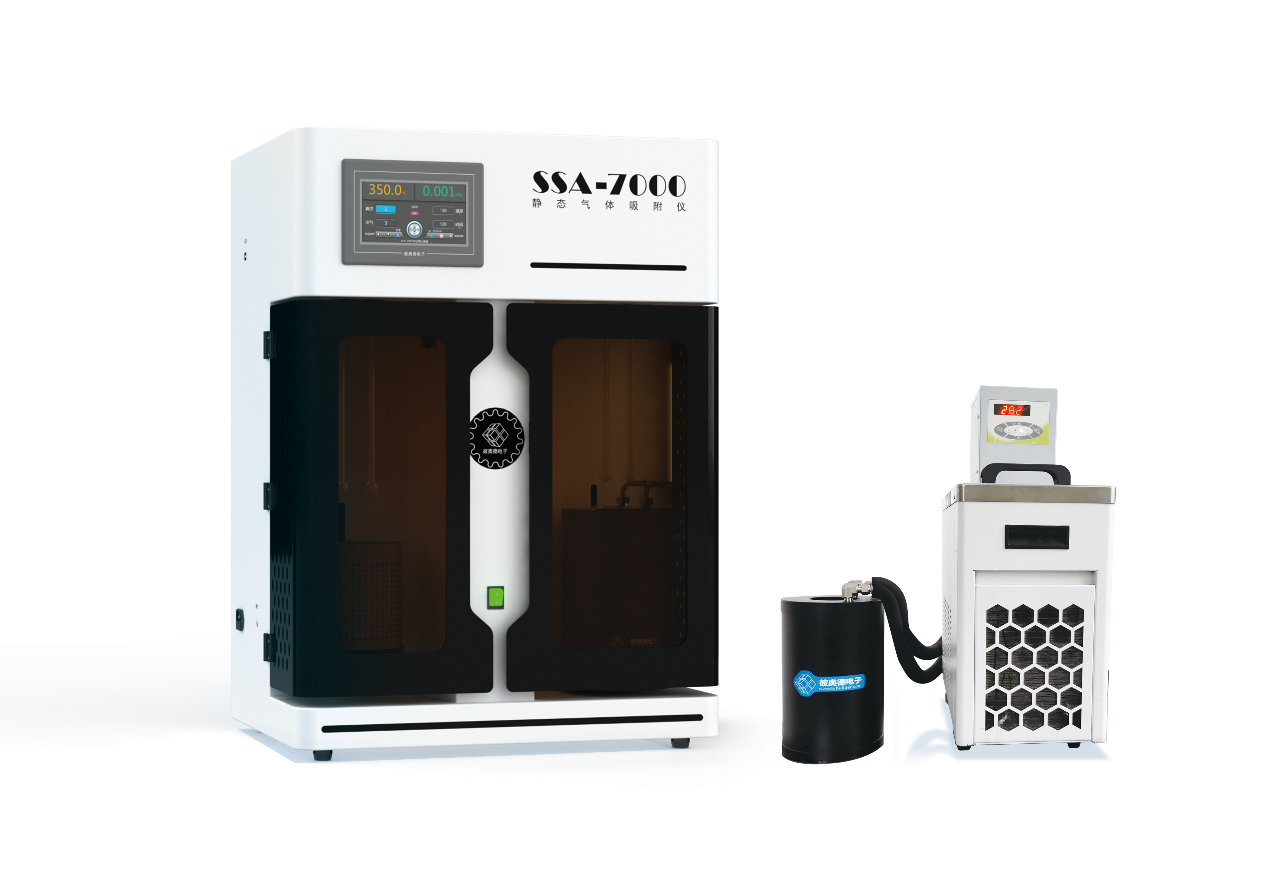

The SSA-7000 specific surface area and aperture analyzer and TD-2200 true density analyzer manufactured by Builder Electronic Technology Co., Ltd. play an important role in detecting the density and material properties of semiconductor and optical component materials. Excellent performance can analyze small parameter differences in materials.

contact

Be the first to know about our new product launches, latest blog posts and more.Any question or request?

Click below, we’ll be happy to assist. contact