The SSA- 7000 Static multi- purpose gas adsorption analyzer is an instrument with excellent testing capability and accuracy, which can accurately analyze microporous ( 0 . 35 - 2 nm) and conventional mesoporous and microporous ( 2 - 500 nm) samples. The performance is more outstanding for 0.35 -0.7 nm micropore testing and testing of samples with very low specific surfaces (< 1 ㎡/g). With advanced technology,excellent quality and more comprehensive theoretical model, the single analysis station design makes it more able to play the advantages of stability and data reproducibility to meet the needs of scientific research and academic discussion and other applications .

Design- advantage

Fast and Efficient Use

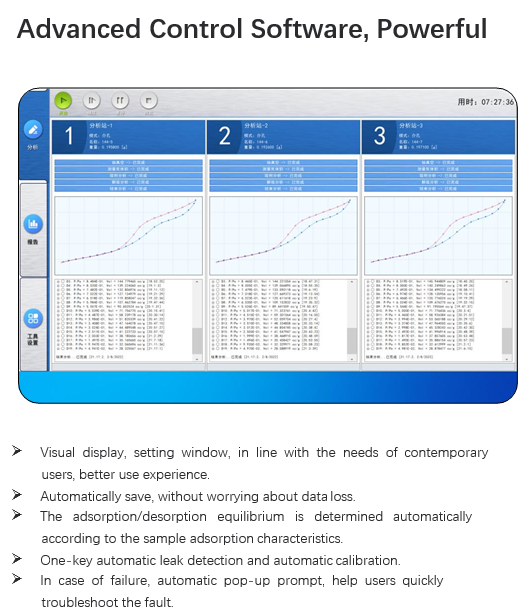

SSA-7000 sample analysis and degassing pretreatment can be performed synchronously or asynchronously; PFC high precision pressure electronic control system greatly reduces the vacuum time; Dynamic gas injection and adsorption balance self-detection increase the test speed by up to 50%.

Stable and Accurate Results

Unique ultra-high vacuum bistable valve body, "0" heating; The pressure test of B-ST technology, the most true feedback of the adsorption state after each injection; Leading temperature difference dynamic calibration technology, to achieve the test time and dead volume quantitative dynamic calibration; The gas path constant temperature system is also a necessary condition for micro test technology and data stability; The 32-bit digital-to-analog conversion accuracy greatly improves the resolution of the pressure sensor.

Very Low Probability of Failure

SSA-7000 adopts high quality and high performance brand parts, each part is around our core technical service, and we have superb manufacturing process, we are the "maker" of the instrument, rather than the "porter" of the parts.

After soaking in liquid nitrogen, the whole system is vacuumed first, and then nitrogen is injected into the sample tube at a certain pressure. After adsorption equilibrium, the pressure at this time is detected, and the adsorption amount is calculated according to the change of pressure difference before and after adsorption. The adsorption isotherm was obtained when P/Po≈1. The desorption process is on the contrary. The system that has been adsorbed and saturated is vacuumed to discharge nitrogen, and the desorption amount is calculated according to the pressure difference between the front and the back until all nitrogen is discharged and the desorption line is obtained.

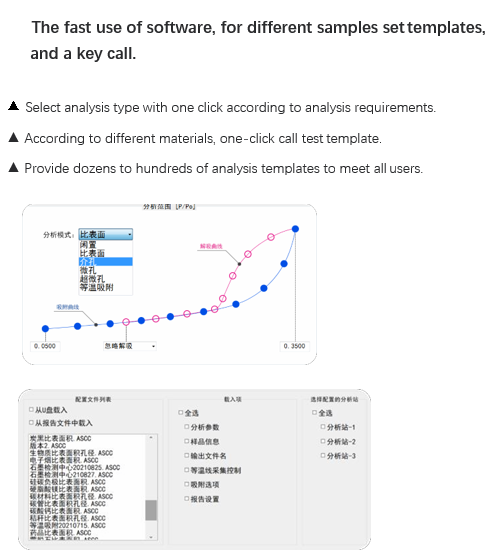

Analysis model:

Adsorption and desorption isotherm gas adsorption curve

BET specific surface area measurement of pore volume aperture distribution by BJH method Langmuir specific surface area HK/MP/SF micropore analysis

t-plot /αs aperture analysis DR Method microhole analysis

t-plot/αs surface area analysis DFT micromesoporous analysis

AI intelligent degassing station to solve the problem of sample preparation

1.For the initial analysis, it is not clear how much time can be set before the water in the sample can be cleaned?

▲ One key select "AI" intelligent mode, automatically judge the completion of processing, automatically stop, automatically record the total time, to provide conditions for the next preparation.

2. My sample has a large water content, which is easy to "boil/analyze" under vacuum. How should I deal with it?

▲ One key to select the "multi water" mode, to solve the problem of failure in the preparation of chromatography.

3. Boehmite/alumina and other ultra-fine powder, graphene/white carbon black and other ultra-light powder, easy to "boil" under vacuum should be how to deal with?

▲ One key to select "ultra-light" mode to solve the problem of boiling preparation failure.

1、Analytical Functions: vacuum static volumetric method, adsorption and desorption isotherm, BET/Langmuir specific surface area, BJH pore volume/pore area/total pore volume/total pore area analysis. Micropore analysis such as t-plot/MP/HK/SF/DR/Argon or carbon dioxide analysis of special micropore samples/isothermal adsorption (adsorption amount) test.

2、Test Range: specific surface area ≥0.0005m2/g, aperture analysis 0.35nm-500nm; Relative pressure P/P0 partial pressure range can be controlled to -0.998; 10-8 ~ 0.998 or 10-6 ~ 0.998.

3、Analysis Accuracy: specific surface area, ±1%; Aperture repetition deviation ≤0.02nm.

4、Analysis Station: 1 or 2, can carry out ultra-micro pore, micro pore, mesoporous, large pore and ultra-low adsorption material accurate analysis, equipped with 4L super-large capacity dewar bottle.

5、Po Test Station: 1 liquid nitrogen saturated vapor pressure test station equipped with an independent sensor for real-time detection. In order to obtain the true value of Po, it is necessary to share the same liquid nitrogen bath with the analysis station.

6、Adsorbed Gas: N2/Kr/Ar/CO2/CH4/H2/CO2/C2H2/NH3/SO2.

7、Instrument Specifications: length 700mm, width 480mm, height 905mm; Total power 1000W (main engine and pump); Operating voltage 220.

8、Hardware System Control.

8.1、Gas path control system: adopting an integrated gas path to reduce "leakage points".

8.2、Data acquisition system: high-precision 32-bit analog-to-digital conversion system, usb communication and transmission interface.

8.3、Pressure detection system: equipped with multiple pressure sensors of different ranges and independent pressure sensors for steam pressure testing, real-time collection of saturated steam pressure; The software can display and view pressure values in real-time.

8.4、Vacuum system: The host is equipped with an imported two-stage rotary vane mechanical pump and a turbomolecular pump, with a maximum vacuum of 10-8Pa; The molecular pump is equipped with an independent pressure assistance system, which improves its service life and analysis efficiency.

8.5、Dynamic calibration technology of temperature difference: solves the impact of liquid nitrogen volatilization on quantitative measurement, effectively improving the testing accuracy and stability of the instrument; Can be applied to coolants at different temperatures.

8.6、Control system: High vacuum self-locking valve, "0" heating, solving the impact of heating on detection.

9、MD-200S Intelligent Sample Degassing Station:

9.1、Vacuum heating and degassing of 2 samples can be carried out at the same time, with the upper temperature of 400℃.

9.2、he degassing station is equipped with an independent vacuum system and vacuum pump, which improves the efficiency of degassing and testing.

9.3、Using an isothermal heating furnace, the sample is heated more evenly and has a longer service life.

9.4、AI Intelligent Degassing System can Select "Multi-Water", "ultra-light", "standard" and other treatment solutions according to the sample type.

contact

Be the first to know about our new product launches, latest blog posts and more.Any question or request?

Click below, we’ll be happy to assist. contact