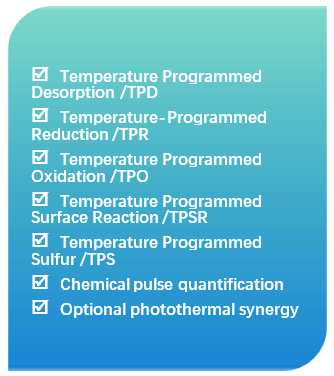

The PCA-1200 series chemical adsorption analyzer is an important characterization equipment for in-situ characterization of catalysts/analysis of surface active site characteristics. It is widely used in fields such as catalysts, fuel cells, energy storage materials, catalytic cracking, catalytic hydrogenation, catalytic reforming, water gas conversion, and automotive exhaust purification. By using the principle of continuous flow chromatography and programmed temperature rise technology, TPAT analysis of various inorganic/organic gases, pulse chemical adsorption, surface reaction, and specific surface area testing are achieved. At the same time, it can be combined with various detection devices, such as online mass spectrometry MS, chromatographic GC, infrared, gas analyzers, etc., to improve the synchronous detection accuracy of complex reactions and products.

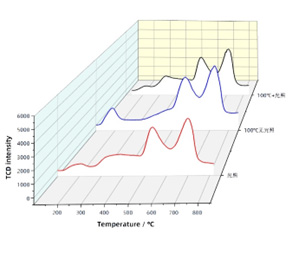

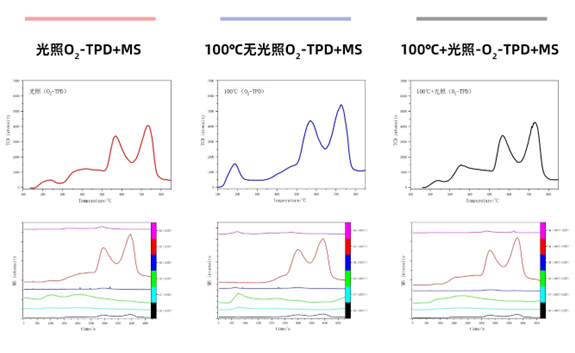

Different catalytic systems have their unique advantages and disadvantages, such as high photocatalytic selectivity but low yield; Thermal catalysis has high yield, but low selectivity and high energy consumption.

Photothermal catalysis combines photochemical and thermochemical reactions, where the heat generated by the photothermal effect facilitates the progress of the reaction, and the photochemical effect also makes the reaction more active. This combination greatly enhances catalytic activity and even changes the way the reaction proceeds. It is very important to design catalysts with a wide light absorption range, high photothermal conversion efficiency, and catalytic activity.

● Adsorbent (Excluding Strongly Corrosive, Highly Toxic, and Hazardous Components)

·Inorganic gases: NH3, CO2, N2, H2, O2, CO, NOx, SO2, H2S, etc

● Catalytic Reactor

·High temperature resistant U-shaped quartz reactor, patent number ZL 2020 2 0472973.6

·Design overflow channels to prevent sample or sample effluent from contaminating the gas path

·The thermocouple is placed at the center of the reactor bed without direct contact with the catalyst, accurately obtaining the bed temperature and the temperature inside the reactor, improving temperature control accuracy and thermocouple service life

● Detector

·Unique four wall PT gold-plated constant temperature TCD detector, patent number ZL 2020 2 0913685. X; Has strong antioxidant and ammonia corrosion resistance capabilities, stable current control ensures baseline stability and test reproducibility signals

·TCD constant temperature: 0-300 ℃, constant temperature accuracy: 0.1% FS, independent control switch, only needs to be turned on during testing, software automatic or manual control; No gas protection, automatic shutdown

·Recommend pairing with online mass spectrometer/chromatography/gas analyzer to achieve synchronous detection of complex components

● Flow Control

·Gas interface: 6 channels (2 carrier gas, 3 reaction/processing gas, 1 pulse gas)

·Mass Flow Controller (MFC): Multiple sets of high-precision digital mass flow controllers, 0-100ml/min, optional for other specifications; Support custom use of flow controllers with different ranges

·In addition to high-purity gases, it can also achieve conversion coefficients for mixed gases of different concentrations, achieving precise control

● Gas Path Control

·Control: High precision twelve in one pulse electromagnetic valve control module, six way valve quantitative control module, can set flow rate and convert gas coefficient through software

Structure: Set up multiple bypasses and intelligently switch according to experimental steps

·Pulse quantification: electric six way valve, loop 200 μ L (standard configuration), other specifications optional 50 μ L/100 μ L/500 μ L, etc

● Temperature Control

·Programmable catalytic reaction furnace: RT~1200 ℃, temperature control accuracy 0.1 ℃; Support 10 different heating and cooling rates; Upgradeable to photothermal programmable furnace, patent number ZL 2021213747494

·High precision of low-temperature constant temperature control (RT~80 ℃), good linearity of low-speed heating at 1-5 ℃/min

·Support the modification of target conditions under heating conditions (unique) to reduce the failure rate of experiments

·Adjustable electric furnace+through type strong air cooling system, can quickly achieve cooling from the highest temperature to room temperature, with a cooling time of less than 25 minutes

● Software Control

·Multiple automated programs (also manual), convenient for beginners to use, automatic storage of experimental steps, graphs, and work logs, convenient for calling and viewing

Each module can be operated and operated independently

visually displaying the status of each component, and real-time drawing of signal and temperature lines

·Provide peak selection, editing, integration, multi peak comparison, and data smoothing processing, and can manually annotate TM and other data

·Can generate TXT, EXCEL and other data files, and can be directly imported into software such as drawing origin

● Instrument Specifications

·The host is 600mm long, 420mm wide, and 700mm high; Power: 800W; Voltage: 220V

contact

Be the first to know about our new product launches, latest blog posts and more.Any question or request?

Click below, we’ll be happy to assist. contact