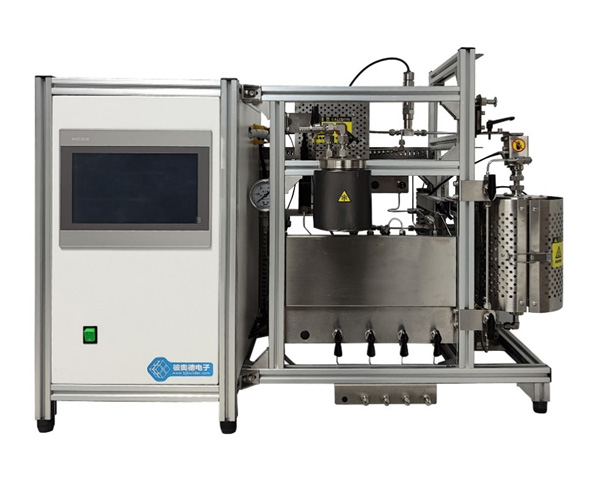

VOC0401 Adsorption and Catalytic evaluation device is a catalytic reaction and adsorption reaction platform that can simulate the concentration of various gas components under small positive pressure. Open frame structure and modular flow temperature control and acquisition system are adopted to provide more possibilities for experiment expansion and scheme change. Designed external saturated steam blowoff system and new gas preheater mixer for better concentration mixing and generation stability.

NO.1 More Stable and Reliable Saturated Steam Occurs

(1)To achieve effective control of the temperature zone of the saturation generator and improve stability

Effective constant temperature liquid volume: 0.5L

Constant temperature circulating solution temperature: -5 ~ 100℃

(2)Convenient disassembly structure, easy to replace the solvent bottle

Solvent bottle sealing method: spinning soft dense (fluorine glue,

butyl cyanide and other options)

Solvent bottle capacity: 30ml

Spiral gas introduction tube, reduce the influence of controller control fluctuations

gas introduction tube length: > 1.5m

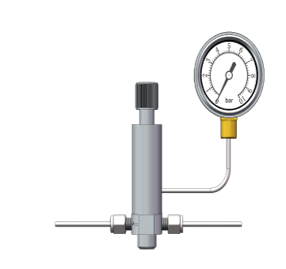

NO.2 Two-stage Voltage Regulator System to Improve MFC Stability

(1)Provides a stable front intake pressure for the mass flow controller

(2)It mainly serves the low-flow working state when low-concentration pollutants occur

(3)It is composed of two parts: pressure gauge and pressure regulator

NO.3 Sample Tube Mounting Structure Without Cold Point

(1)The mounting structure can be lifted and rotated for easy installation

(2)The isothermal structure protects the outer part of the sample tube furnace body at constant temperature, and realizes the "real" no cold point at the inlet port of the reactor

(3)Open interface, can add humidity, pressure, temperature and other detection components in the inlet end of the reactor and inside the reactor

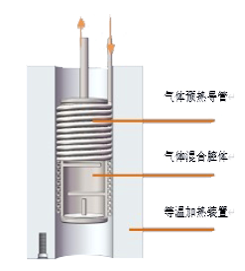

NO.4 Reasonable Gas Preheating and Mixing System

(1)Spiral gas preheating tube with effective preheating length of 1.5m

(2)Gas mixer design baffle, gas preheater volume: 50ml

(3)Gas preheater operating temperature range: room temperature ~300℃

1. Feeding System |

1.1 Configure 4 mass flow controllers, low flow VOC generation is equipped with American ALICAT, configure secondary voltage regulator. |

1.1.1 VOC occurrence: alicat differential pressure low flow controller (optional specification 10\15\20ml/min). |

1.1.2 Humidity simulation and balance gas: horibar thermal flow controller, size 200ml/min. |

1.1.3 Interference components and balance gas: horibar thermal flow controller, specification 200ml/min. |

1.1.4 Sample preparation and preparation gas: horibar thermal flow controller, 500ml/min. |

1.2 Total gas volume: 0 ~ 700ml/min (maximum range of practical application) VOC concentration ≥ 500ppb (Reference: toluene pollutant of total air volume 200ml/min). |

2. Steam Generation System |

2.1 Low temperature saturation blow-off system, blow-off bottle 10/20/30ml optional. |

2.2 External embedded water bath jacket saturated steam generation tank, effective constant temperature liquid volume 0.5L. |

2.3 The temperature is -5℃ ~ 100℃. |

2.4 Design spiral gas inlet tube, length > 1.5m, reduce the influence of controller control fluctuation. |

3. Humidity Generating System |

3.1 Saturated blow-off tank and humidity sensor (Rodronik 200℃, to meet the pipeline 150℃ use requirements). |

3.2 Occurrence temperature RT ~ 130℃. |

3.3 Design the diverter valve. |

4. Gas Preheating Mixing and Pipe Insulation System. |

4.1 The length of spiral gas preheating pipe is greater than 1.5m, φ3. |

4.2 The air mixing chamber adopts baffle structure with a volume of 50ml. |

4.3 Mixer temperature range: room temperature -300℃. |

4.4 Pipe insulation: RT ~ 150 ° C. |

5. Reaction Furnace |

5.1 Operating temperature: RT ~ 800℃, design temperature 1000℃. |

5.2 Open furnace body, aluminum isothermal and polycrystalline mullite insulation, light window (customizable). |

5.3 The inlet and outlet port of the reactor is designed for thermal insulation, no condensation and no drip. |

5.4 Sample size: 0.05-1g (< 2ml). |

6. Tail Gas Interface:The reserved installation interface can be connected to GC and MS, and the exhaust gas interface can be designed according to the product. |

contact

Be the first to know about our new product launches, latest blog posts and more.Any question or request?

Click below, we’ll be happy to assist. contact